Amazing job!

Amazing job!

So, it's been a while since I last posted, but a lot has happened too. New job, big move, and all kinds of little things, including solid progress on my XB.

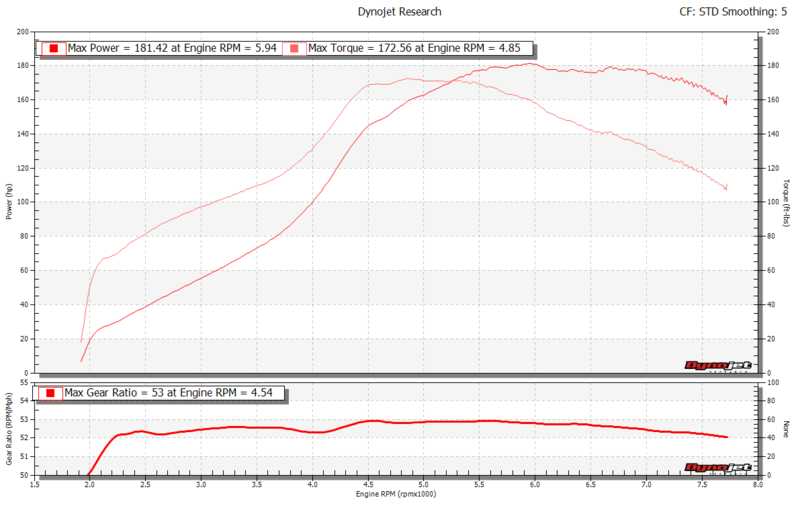

I further upgraded my clutch setup, modifying the Barnett Scorpion clutch with a new pressure plate of my own design and grafted on the hydraulic slave cylinder and pneumatic diaphragm from a Buell 1125 clutch. I re-purposed the diaphragm to provide supplemental force to the clutch under boost, allowing me to run lighter clutch springs for an easier lever pull. I also had the wheels polished and black nickel plated. Latest dyno results proved the clutch design works just as I had hoped for. 180 hp / 172ft-lbs and it is a killer to ride! So much fun and it power wheelies in every gear!

The torque curve tells me that the cylinder heads may be the limiting factor at this point. Everything else is well equipped to see north of 200hp. The head port have minimal work (I just blended the ports to the seats and smoothed the parting lines). I have a call into Aaron and Dan at Hammer to put together a plan for new cylinder head work that will support my HP goals.

This dyno run includes some detonation at the top end but I retarded a couple degrees further and it smoothed right out. This is @ 21psi on 93 pump gas:

I wondered where you went! Great dyno numbersand the wheels turned out spectacular. Awesome and well thought out.

Any more info on the hybrid clutch set up? Converted to hydraulic, but how did you use the diagram to provide additional force under boost? Is that code for running a boost line to the back side of the diaphragm? Does that give you vacuum there at idle and pull the clutch off?

I must have missed it, do you have a RR case, or did you machine the trap door too?

Cooter, the diaphragm allows the clutch to function as a slipper on the 1125 models. It uses high engine vacuum to relieve pressure on the clutch pack by pulling on the pressure plate just as the slave cylinder does when you pull in the lever to disengage the clutch. My setup has a different throw out bearing in the pressure plate that handles thrust loads from either direction. Now, the throwout bearing supports the thrust loads from disengaging the clutch with the lever or during high engine vacuum AND it handles thrust loads in the opposite direction when boost pressure is generated at high engine loads, applying more force to the clutch pack. I used a diaphragm support plate on both sides of the diaphragm to make this work. The outer support plate is the same as what the 1125 uses. I modified the shape of another support plate to use as the inner. Only the outer side sees vacuum/boost pressures from the manifold, just as the 1125, and the inner side is vented to atmospheric.

For comparison, prior to adding this setup, I had to use 600lbs of clutch spring force to hold the engine's torque, but that required too much lever effort, so I ran 480lbs of spring and turned the boost down. Now, I have 220lbs of spring force and it holds all the torque I can throw at it.

Cole, I just used a set of 3.6 cases I had as a fixture to machine the primary cover. I have since sold the cases to Mark White. My engine uses cases from a 2007 XB9 (same as any 2006-2007 XB).

Thank you for the detail Eric. That's an impressive way to think outside the box for your boosted application. Do they do that with high end boosted autos? I must say I'm surprised that at 6-8psi(?) it adds that much force from just the diaphragm! From slipping with 600lb springs, to solid at 220lb springs means you are probably tripling the pressure on the clutch pack. Must be a nice TO bearing ($$$).

It works great! I don't think this concept has made its way into the auto industry since clutch diameters are plenty large for the torque output. I recently learned that NLR makes a similar setup for boosted Hayabusas: http://www.nlrsystems.com/boost-cont...r-boost-lockup

The force from the diaphragm is proportional to the diaphragm's effective surface area. This setup equates to a ratio of 20lbs of force per 1psi of boost. I peak at 21psi of boost so the diaphragm is adding +420lbs of force to the clutch or 640lbs total @ 21psi of boost. The throwout bearing does not have to deal with any more force than before, just in both directions and only when under boost or when I'm pulling in the lever. The old throwout bearing had to deal with 480-~560lbs of force every time I pulled in the lever. Now, it only sees 220-~300lbs when I pull in the lever and up to 420lbs in the other direction only while under boost. I'm using a 3200 bearing. It's a double row angular contact ball bearing. It handles ~800lbs of axial force for infinite life so it should hold up just fine.

You max at 21 psi on a V-twin!?! Holy shnikies! I need to re-read this thread....

You da man...man

Eric I saw your bike on YouTube and thought it was really cool. Showed all my buddies. Had no idea you were in these chats. Just wanted to tell you that I really appreciate the craftsmanship and work you have done. 👍